Ingaba isebenza kanjani

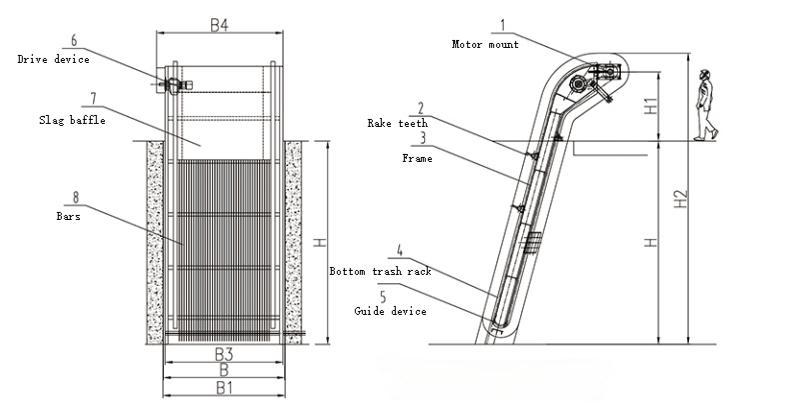

Njengoko amanzi amdaka okanye amanzi aluhlaza edlula kwiscreen, inkunkuma enkulu kunesithuba sescreen iyabanjwa. Amazinyo ereyiki kwipleyiti yereyiki enamazinyo angena kwizikhewu eziphakathi kweebhari ezizinzileyo, ephakamisa izinto ezithintelweyo phezulu njengoko iyunithi yokuqhuba ijikeleza uthotho lokutsala.

Xa amazinyo ereyikhi efikelele kwinqanaba lokukhupha, inkunkuma iwela kwinkqubo yokuhambisa impahla ngenxa yomxhuzulane ukuze isuswe okanye iqhubeke nokucubungula. Le nkqubo yokucoca ngokuzenzekelayo iqinisekisa ukusebenza okuqhubekayo nokusebenza kakuhle ngaphandle kokungenelela ngesandla.

Ezona mpawu

-

1. Inkqubo yokuqhuba ethembekileyo

-

Iqhutywa yi-cycloidal pinwheel okanye i-helical gear motor

-

Ingxolo ephantsi, isakhiwo esincinci, kunye nokusebenza okuzinzileyo

-

-

2. Amazinyo eRake anzima

-

Amazinyo adityanisiweyo anencam ye-bevel afakwe kwi-shaft ethe tye

-

Uyakwazi ukuphakamisa inkunkuma enkulu eqinileyo ngokufanelekileyo

-

-

3. Uyilo lwesakhelo oluqinileyo

-

Ulwakhiwo lwesakhelo esidibeneyo luqinisekisa ukuqina okuphezulu

-

Ukufakela okulula kunye neemfuno ezincinci zokugcinwa kwemihla ngemihla

-

-

4. Ukusebenza okulula ukusebenziseka

-

Ixhasa ulawulo olukwindawo okanye olukude ukuze isebenze ngokuguquguquka

-

-

5. Ukhuseleko oluphindwe kabini

-

Ixhotyiswe ngezikhonkwane zokucheba ngoomatshini kunye nokhuseleko olugqithisileyo

-

Ithintela ukonakala kwezixhobo ngexesha lokugqithisa kakhulu

-

-

6. Inkqubo yoLungiso lweSibini

-

Isikrini sesibini sifakwe ezantsi kweyunithi

-

Xa amazinyo ereyiki ehamba ukusuka ngasemva ukuya ngaphambili kwesikrini esiphambili, i-gring yesibini ingena ngokuzenzekelayo ukuthintela ukuhamba kwe-bypass kunye nokuqinisekisa ukubanjwa kwenkunkuma ngokufanelekileyo

-

Izicelo

-

✅Iifektri zokucoca amanzi amdaka zikamasipala nezemizi-mveliso

-

✅Iindawo zokungenisa amanzi emilanjeni kunye nezikhululo zokumpompa amanzi nge-hydraulic

-

✅Ukuhlolwa okucothayo ngaphambi kokuba kuhluzwe iiyunithi zokucoca

-

✅Amanqanaba angaphambi konyango kwiinkqubo zobonelelo lwamanzi

Iiparameters zobugcisa

| Imodeli | I-HLBF-1250 | I-HLBF-2500 | I-HLBF-3500 | I-HLBF-4000 | I-HLBF-4500 | I-HLBF-5000 |

| Ububanzi bomatshini B(mm) | 1250 | 2500 | 3500 | 4000 | 4500 | 5000 |

| Ububanzi betshaneli B1(mm) | B1=B+100 | |||||

| Ubungakanani be-mesh b(mm) | 20~150 | |||||

| I-engile yokufakela | 70~80° | |||||

| Ubunzulu betshaneli H(mm) | 2000~6000 (Ngokweemfuno zomthengi.) | |||||

| Ukuphakama kokukhupha i-H1(mm) | 1000~1500 (Ngokweemfuno zomthengi.) | |||||

| Isantya sokubaleka (m/Min) | Malunga ne-3 | |||||

| Amandla enjini N(kW) | 1.1~2.2 | 2.2~3.0 | 3.0~4.0 | |||

| Umthwalo wemfuno yobunjineli bokwakha i-P1(KN) | 20 | 35 | ||||

| Umthwalo wemfuno yobunjineli bokwakha i-P2(KN) | 20 | 35 | ||||

| Umthwalo wemfuno yobunjineli bokwakha △P(KN) | 2.0 | 3.0 | ||||

Qaphela: I-P1(P2) ibalwa ngo-H=5.0m, kwi-1m nganye i-H eyonyusiweyo, emva koko i-P iyonke=P1(P2)+△P

Ubukhulu

Izinga lokuhamba kwamanzi

| Imodeli | I-HLBF-1250 | I-HLBF-2500 | I-HLBF-3500 | I-HLBF-4000 | I-HLBF-4500 | I-HLBF-5000 | ||

| Ubunzulu bamanzi ngaphambi kwesikrini H3 (mm) | 3.0 | |||||||

| Izinga lokuhamba kwamanzi (m/s) | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | ||

| Ubungakanani be-mesh b (mm) | 40 | Izinga lokuhamba kwamanzi (l/s) | 2.53 | 5.66 | 8.06 | 9.26 | 10.46 | 11.66 |

| 50 | 2.63 | 5.88 | 8.40 | 9.60 | 10.86 | 12.09 | ||

| 60 | 2.68 | 6.00 | 8.64 | 9.93 | 11.22 | 12.51 | ||

| 70 | 2.78 | 6.24 | 8.80 | 10.14 | 11.46 | 12.75 | ||

| 80 | 2.81 | 6.30 | 8.97 | 10.29 | 11.64 | 12.96 | ||

| 90 | 2.85 | 6.36 | 9.06 | 10.41 | 11.70 | 13.11 | ||

| 100 | 2.88 | 6.45 | 9.15 | 10.53 | 11.88 | 13.26 | ||

| 110 | 2.90 | 6.48 | 9.24 | 10.62 | 12.00 | 13.35 | ||

| 120 | 2.92 | 6.54 | 9.30 | 10.68 | 12.06 | 13.47 | ||

| 130 | 2.94 | 6.57 | 9.36 | 10.74 | 12.15 | 13.53 | ||

| 140 | 2.95 | 6.60 | 9.39 | 10.80 | 12.21 | 13.59 | ||

| 150 | 2.96 | 6.63 | 9.45 | 10.86 | 12.27 | 13.65 | ||