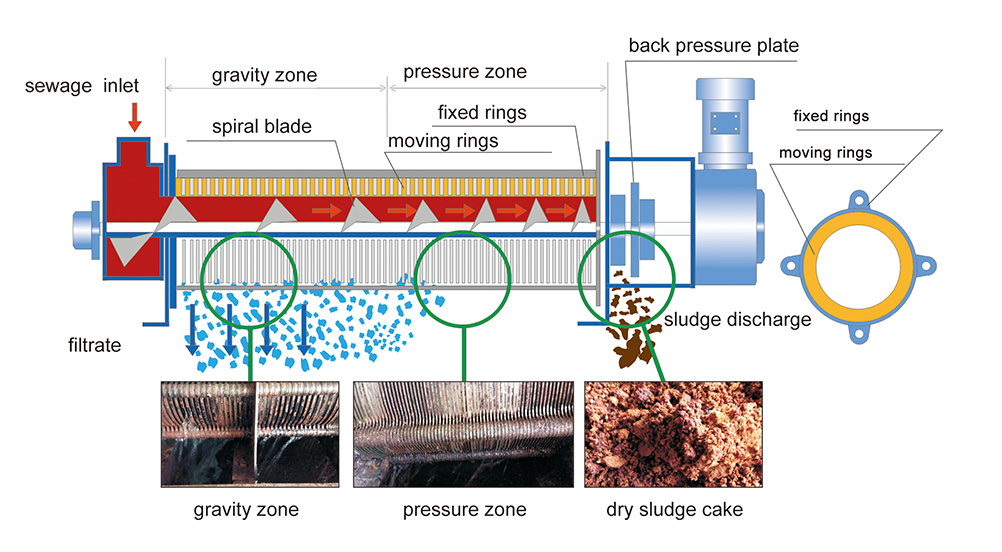

UmGaqo wokuSebenza:

I-sludge ene-conditioning ifakwe kwindawo yokukhupha amanzi ukusuka kwitanki ye-flocculation. Njengoko iqhubela phambili ngezikhewu ezicuthayo ezenziwe yi-screw shaft kunye nezangqa ezihambayo, uxinzelelo luyakhula kwaye amanzi aphuma kancinci kancinci.

Amanzi ahlukeneyo ahamba ngezithuba phakathi kweendandatho ezihambayo kunye nezilungisiweyo, ezihlanjululwa ngokuzenzekelayo ngokuhamba kweendandatho ngokwazo-ngokuthintela ngokufanelekileyo ukuvala kunye nokuqinisekisa ukusebenza okuqhubekayo. Ikhekhe le-sludge elixinyiweyo ekugqibeleni liyakhutshwa ekugqibeleni.

Ezona mpawu:

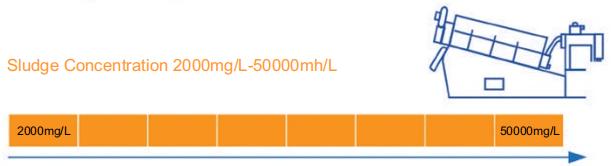

Ugxininiso lwangaphambili lwe-sludge ephantsi-concentration

Uxhotyiswe ngepleyiti ye-spiral ekhethekileyo, umatshini wenza ngokufanelekileyo ugxininiso lwangaphambili, okwenza ukuba lulungele ngokukodwa ukunyanga i-sludge ephantsi. Ngokutshintshela i-dehydrators yendabuko yohlobo lomxhuzulane kunye nokudibanisa i-flocculation kunye neenkqubo zoxinaniso, yenza lula unyango lwe-sludge. Ivalve yokulawula i-solenoid iqhubela phambili iphucula ugxininiso lwe-slurry ukuze kuphuculwe ukwenziwa kwamanzi.

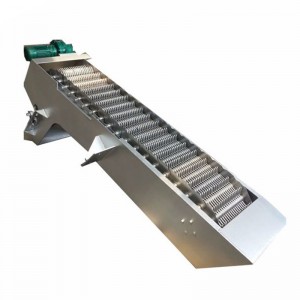

1. I-Clog-Free Design enezangqa zokuzicoca

I-HLDS isebenzisa iindandatho ezihambayo kunye nezilungisiweyo endaweni yeengubo zokucoca, ukuphelisa imiba yokuvala kunye nokunciphisa iimfuno zokugcina. Ilungele ngokukhethekileyo i-oily and low-concentration sludge, kwaye ayifuni ukucocwa koxinzelelo oluphezulu, ukunciphisa ukungcola okwesibini.

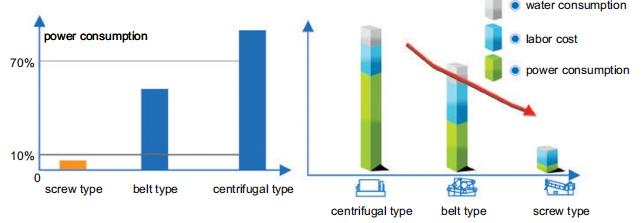

2. I-Speed-Speed-Low, i-Energy-Efficient Operation

Ngesantya sokujikeleza esisezantsi kakhulu kuneso sebhanti okanye iinkqubo ze-centrifugal, i-HLDS screw press inciphisa ukusetyenziswa kwamandla ukuya kwi-87.5% xa kuthelekiswa noxinzelelo lwebhanti kunye ne-95% xa kuthelekiswa ne-centrifuges. Ikwavelisa ingxolo encinci ngexesha lokusebenza.

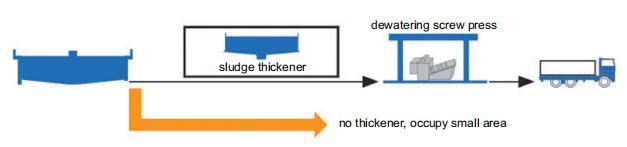

3. IziSeko ezinguNdoqo eziNcitshisiweyo kunye neeNdleko zokuSebenza

Umatshini wokukhupha amanzi we-screw sludge unokunyanga i-sludge ngokuthe ngqo kwi-aeration kunye ne-sedimentation tanks, ukuphelisa imfuno yokuqina kwamatanki kunye nokunciphisa ukukhutshwa kwe-phosphorus. Ifuna indawo ephantsi yomgangatho ophantsi, ekhokelela kutyalo-mali olusezantsi kwizakhiwo zokucocwa kwamanzi amdaka.

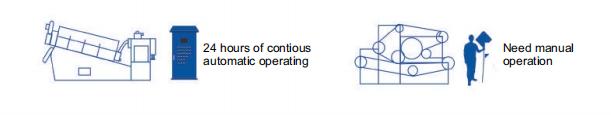

4. Ulawulo oluzenzekelayo kunye nokusebenza okulula

Idityaniswe nekhabhinethi yolawulo yombane esekwe kwi-PLC, inkqubo ixhasa ukusebenza ngokuzenzekelayo. Ukungabikho kwamacandelo e-clog-prone kuqinisekisa ukusebenza okuzinzile, ukugcinwa okuphantsi-okulungele izibonelelo ezifuna i-24/7 yokusebenza engagcinwanga.

Usetyenziso:

Umshicileli we-screw dewatering uguquguquka kakhulu kwaye usebenza kuluhlu olubanzi lweentlobo zodaka kunye namashishini:

- ✅ Ukucocwa kwamanzi amdaka kumasipala

- ✅ Amashishini epetrochemical kunye neekhemikhali

- ✅ I-Pulp & nezixhobo zephepha

- ✅ Izityalo ezixuba amayeza kunye nokudaya

- ✅ Inyama kunye nemveliso yobisi

- ✅ Amanzi amdaka emigodini

- ✅ Imizi-mveliso yokushicilela nokupeyinta

- ✅ Udaka lwetanki yeSeptic

- ✅ Ioli yesundu kunye nenkunkuma yasefama yobisi

Nokuba ulawula i-sludge esebenzayo, i-DAF sludge, i-sludge exutywe, okanye i-sludge enekhemikhali, lo matshini wokucofa amanzi wokucoca uqinisekisa ukusebenza kakuhle kunye nembuyekezo kutyalo-mali.

Iiparamitha zobuGcisa:

| Uhlobo | Amanzi amdaka akrwada / iNkunkuma eVunyiweyo / udaka oluneMichiza | Udaka Lomoya Onyibilikisiweyo | I-Mixed Raw Sludge | ||

| Ukuxinana kodaka (TS) | 0.20% | 1.00% | 2.00% | 5.00% | 3.00% |

| I-HLDS-131 | ~4kg-DS/h(~2.0m³/h) | ~6kg-DS/h(~0.6m³/h) | ~10kg-DS/h(~0.5m³/h) | ~20kg-DS/h(~0.4m³/h) | ~26kg-DS/h(~0.87m³/h) |

| I-HLDS-132 | ~8kg-DS/h(~4.0m³/h) | ~12kg-DS/h(~1.2m³/h) | ~20kg-DS/h(~1.0m³/h) | ~40kg-DS/h(~0.5m³/h) | ~52kg-DS/h(~1.73m³/h) |

| I-HLDS-133 | ~12kg-DS/h(~6.0m³/h) | ~18kg-DS/h(~1.8m³/h) | ~30kg-DS/h(~1.5m³/h) | ~60kg-DS/h(~1.2m³/h) | ~72kg-DS/h(~2.61m³/h) |

| I-HLDS-201 | ~8kg-DS/h(~4.0m³/h) | ~12kg-DS/h(~1.2m³/h) | ~20kg-DS/h(~1.0m³/h) | ~40kg-DS/h(~0.8m³/h) | ~52kg-DS/h(~1.73m³/h) |

| I-HLDS-202 | ~16kg-DS/h(~8.0m³/h) | ~24kg-DS/h(~2.4m³/h) | ~40kg-DS/h(~2.0m³/h) | ~80kg-DS/h(~1.6m³/h) | ~104kg-DS/h(~3.47m³/h) |

| I-HLDS-203 | ~24kg-DS/h(~12.0m³/h) | ~36kg-DS/h(~3.6m³/h) | ~60kg-DS/h(~3.0m³/h) | ~120kg-DS/h(~2.4m³/h) | ~156kg-DS/h(~5.20m³/h) |

| I-HLDS-301 | ~20kg-DS/h(~10.0m³/h) | ~30kg-DS/h(~3.0m³/h) | ~50kg-DS/h(~2.5m³/h) | ~100kg-DS/h(~2.0m³/h) | ~130kg-DS/h(~4.33m³/h) |

| I-HLDS-302 | ~40kg-DS/h(~20.0m³/h) | ~60kg-DS/h(~6.0m³/h) | ~100kg-DS/h(~5.0m³/h) | ~200kg-DS/h(~4.0m³/h) | ~260kg-DS/h(~8.67m³/h) |

| I-HLDS-303 | ~60kg-DS/h(~30.0m³/h) | ~90kg-DS/h(~9.0m³/h) | ~150kg-DS/h(~7.5m³/h) | ~300kg-DS/h(~6.0m³/h) | ~390kg-DS/h(~13.0m³/h) |

| I-HLDS-304 | ~80kg-DS/h(~40.0m³/h) | ~120kg-DS/h(~12.0m³/h) | ~200kg-DS/h(~10.0m³/h) | ~400kg-DS/h(~8.0m³/h) | ~520kg-DS/h(~17.3m³/h) |

| I-HLDS-351 | ~40kg-DS/h(~20.0m³/h) | ~60kg-DS/h(~6.0m³/h) | ~100kg-DS/h(~5.0m³/h) | ~200kg-DS/h(~4.0m³/h) | ~260kg-DS/h(~8.67m³/h) |

| I-HLDS-352 | ~80kg-DS/h(~40.0m³/h) | ~120kg-DS/h(~12.0m³/h) | ~200kg-DS/h(~10.0m³/h) | ~400kg-DS/h(~8.0m³/h) | ~520kg-DS/h(~17.3m³/h) |

| I-HLDS-353 | ~120kg-DS/h(~60.0m³/h) | ~180kg-DS/h(~18.0m³/h) | ~300kg-DS/h(~15.0m³/h) | ~600kg-DS/h(~12.0m³/h) | ~780kg-DS/h(~26.0m³/h) |

| I-HLDS-354 | ~160kg-DS/h(~80.0m³/h) | ~240kg-DS/h(~24.0m³/h) | ~400kg-DS/h(~20.0m³/h) | ~800kg-DS/h(~16.0m³/h) | ~1040kg-DS/h(~34.68m³/h) |

| I-HLDS-401 | ~70kg-DS/h(~35.0m³/h) | ~100kg-DS/h(~10m³/h) | ~170kg-DS/h(~8.5m³/h) | ~340kg-DS/h(~6.5m³/h) | ~442kg-DS/h(~16.0m³/h) |

| I-HLDS-402 | ~135kg-DS/h(~67.5m³/h) | ~200kg-DS/h(~20.0m³/h) | ~340kg-DS/h(~17.0m³/h) | ~680kg-DS/h(~13.6m³/h) | ~884kg-DS/h(~29.5m³/h) |

| I-HLDS-403 | ~200kg-DS/h(~100m³/h) | ~300kg-DS/h(~30.0m³/h) | ~510kg-DS/h(~25.5m³/h) | ~1020kg-DS/h(~20.4m³/h) | ~1326kg-DS/h(~44.2m³/h) |

| I-HLDS-404 | ~266kg-DS/h(~133m³/h) | ~400kg-DS/h(~40.0m³/h) | ~680kg-DS/h(~34.0m³/h) | ~1360kg-DS/h(~27.2m³/h) | ~1768kg-DS/h(~58.9m³/h) |

| Uhlobo | Ukukhupha Ukuphakama | Imilinganiselo | Ubunzima (kg) | Amandla (kW) | Amanzi okuhlamba (L/h) | |||

| L(mm) | W(mm) | H(mm) | Akunanto | Ukusebenza | ||||

| I-HLDS-131 | 250 | 1860 | 750 | 1080 | 180 | 300 | 0.2 | 24 |

| I-HLDS-132 | 250 | 1960 | 870 | 1080 | 250 | 425 | 0.3 | 48 |

| I-HLDS-133 | 250 | 1960 | 920 | 1080 | 330 | 580 | 0.4 | 72 |

| I-HLDS-201 | 350 | 2510 | 900 | 1300 | 320 | 470 | 1.1 | 32 |

| I-HLDS-202 | 350 | 2560 | 1050 | 1300 | 470 | 730 | 1.65 | 64 |

| I-HLDS-203 | 350 | 2610 | 1285 | 1300 | 650 | 1100 | 2.2 | 96 |

| I-HLDS-301 | 495 | 3330 | 1005 | 1760 | 850 | 1320 | 1.3 | 40 |

| I-HLDS-302 | 495 | 3530 | 1290 | 1760 | 1300 | 2130 | 2.05 | 80 |

| I-HLDS-303 | 495 | 3680 | 1620 | 1760 | 1750 | 2880 | 2.8 | 120 |

| I-HLDS-304 | 495 | 3830 | 2010 | 1760 | 2300 | 3850 | 3.55 | 160 |

| I-HLDS-351 | 585 | 4005 | 1100 | 2130 | 1100 | 1900 | 1.3 | 72 |

| I-HLDS-352 | 585 | 4390 | 1650 | 2130 | 1900 | 3200 | 2.05 | 144 |

| I-HLDS-353 | 585 | 4520 | 1980 | 2130 | 2550 | 4600 | 2.8 | 216 |

| I-HLDS-354 | 585 | 4750 | 2715 | 2130 | 3200 | 6100 | 3.55 | 288 |

| I-HLDS-401 | 759 | 4680 | 1110 | 2100 | 1600 | 3400 | 1.65 | 80 |

| I-HLDS-402 | 759 | 4960 | 1760 | 2100 | 2450 | 5200 | 2.75 | 160 |

| I-HLDS-403 | 759 | 5010 | 2585 | 2100 | 3350 | 7050 | 3.85 | 240 |

| I-HLDS-404 | 759 | 5160 | 3160 | 2100 | 4350 | 9660 | 4.95 | 320 |

-

I-Arhente Yokukhupha Ivumba leeTanki zeSeptic kunye neNkunkuma...

-

Ukukhupha amanzi ngoLudaka oluLungileyo ngePleyiti eQhliweyo...

-

I-Nitrifying Bacteria Agent kunyango lwamanzi amdaka

-

ISkrini esingatshintshiyo saManzi amdaka aManzi aManzi aManzi aMahluko

-

I-Halotolerant Bacteria-i-Bioremed ekwiNzululwazi...

-

Mechanical Bar Screen for aWastewater Pretreatme...